Plasma Cleaning Technology

SEM, FIB and TEM Contamination Solutions

The mission of ibss Group is to not only provide the fastest, safest, and most efficient plasma cleaner on the market, but also to develop and maintain long term relationships with customers and operators of the GV10x by providing quick response times and thorough explanations and support that exceed expectations.

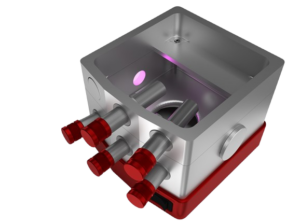

GV10x DS Asher

The GV10x Downstream Asher’s ability to remove carbon contamination is a major advancement over traditional methods of mitigating contamination using cold trapping, nitrogen purging, and other plasma cleaners. The GV10x, with its extended power and pressure range (5 to 100 Watts and 2 to <0.005 Torr), represents a paradigm shift in the carbon decontamination of SEMs and other vacuum systems. Atomic oxygen and hydrogen eliminates contamination by converting the surface carbon into gas phase molecules which are then pumped out of chambers. ibss Group, Inc. offers two different controllers to power and operate GV10x plasma sources. The choice between BT Controller and 2U Controller is a laboratory user preference. The ibss GUI software is compatible with both controllers.

GV10x UHV DS Asher

Competitive sources discovered by internet search may be High Vacuum (HV) but not Ultra-High Vacuum (UHV) compatible. Vacuum components necessary to convert HV plasma sources UHV compatible require an expensive isolation valve and pre-pump components. The GV10x UHV DS Asher is designed to reside on a UHV chamber after chamber plasma cleaning in millitorr range without breaking vacuum. This one of a kind in-situ plasma source eliminates the need for a costly isolation valve and pre-pump. Through an innovative plasma source design, the GV10x UHV Downstream Asher reduces hydrocarbon contamination 10 to 20 times more effectively on synchrotron optics and >10 times faster than traditional methods and plasma cleaners.

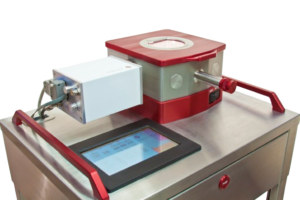

Mobile Cubic Asher (MCA)

A mobile plasma center that cleans, stores and processes SEM/TEM samples/holders and other sundry items in a small chamber. The Qwk-Switch™ Source facilitates shifting hydrocarbon mitigation to other SEM or FIB sites for in-situ chamber cleaning. The MCA chamber accommodates an assortment of specimens to remove hydrocarbons, hydrophilizing surfaces, storing and cleaning three TEM holders and specimens with ibss signature GV10x Downstream plasma fitted onto a portable S/S cart.

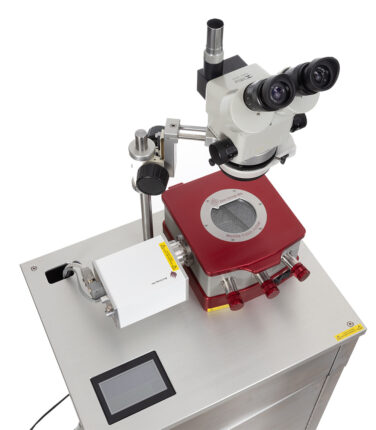

Chiaro

Similar to MCA but distinguished by turbomolecular pressure & speed. An optional optical microscope can be installed to mount and observe specimens during plasma conditioning and potential leak observation from liquid/gas specimen cells. Plasma processing at lower vacuum increases plasma processing activity. To meet requirements of viewing gas and liquid sample cells in TEM holders the Chiaro performs the functions of leak checking, gas/liquid E-Chip viewing while mounting, surface hydrophilization and plasma processing.

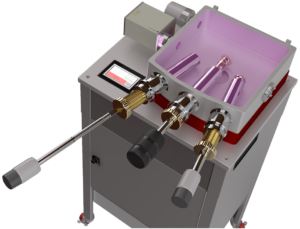

MCA Plasma Storage Expansion 3

MCA chamber capabilities can be expanded to accommodate up to 9 TEM holders with the addition of the Storage Expansion 3 option. This storage expansion for MCA leverages the powerful capabilities and flexibility of ibssGroup’s MCA.

SPex TEM Holder Sleeve for MCA Plasma Cleaner

SPex TEM Holder Sleeve expands the MCA’s capabilities to accommodate TEM holder functionality. SPex for MCA leverages the powerful capabilities and flexibility of ibssGroup’s MCA plasma cleaning station.

Applications

The GV10x DS Asher’s ability to remove carbon contamination from Electron Microscopy samples and chambers is well recognized by electron microscopists worldwide. Contamination control improvements beyond traditional methods: 1st generation plasma cleaners, LN2 trapping, N2 purging offer EM researches freedom to remove carbon artifacts in minutes and mitigate chamber contamination buildup.

Superior GV10x performance results from low pressure plasma production. Slow plasma species recombination and long mean free paths disperse bright UV throughout the chamber volume. The chemical interaction combined with extended power range converts surface carbon into gas phase molecules that are pumped out of chambers – not just immobilized on trapping surfaces.

Although cleaning times vary between instruments depending on contamination loads, the efficient GV10x DS Asher can be shifted to several laboratory microscopes tools to keep all microscopes in the laboratory contamination free. Qwk-Switch™, QSTM mounting facilitates moving one GV10x Source from instrument to instrument.

With the progression of nanoscience, electron beams become more focused, electron beam energies decrease, and precursor gas use is becoming more common. High resolution at low landing energy becomes increasingly dependent on minimizing carbon contamination at low levels. The Asher downstream plasma process accomplishes the tasks quickly, easily saving operator valuable time. Unlike kinetic sputter etch cleaning in usual ‘plasma cleaners’, the downstream plasma process is a gentle chemical etch. The process has revolutionized the means to eliminate carbon molecules and hydrocarbons in vacuum chambers.

SEM, FIB and TEM Applications

Plasma cleaning is the most non-invasive effective way to prepare samples for electron microscopy when outgassing materials are observed. As the plasma cleaning process removes hydrocarbon contamination layers, it can remove other carbon structures at the same time. This can be an issue for TEM application since the carbon support grids become less robust after each cleaning period. ibss offers non-kinetic, gentle mechanism to minimize the side effects of plasma sample interactions. The results show the system effectively removes contamination while preserving the carbon support film for many cleaning runs.

To read the full journal paper, click here.

Load Lock

Cleaning samples in load locks is facilitated by Qwk-Switch mounting and software that automates the cleaning in the load lock and sample entry. Pre-cleaning on the load lock minimize chamber contamination and reduces chamber cleaning. In fact, the load lock door can be opened to clean the chamber. Please contact us for ibss solutions on load lock configurations.

Wakefield Accelerator Optics restoring