Sample preparation for SEM and TEM

For SEM users:

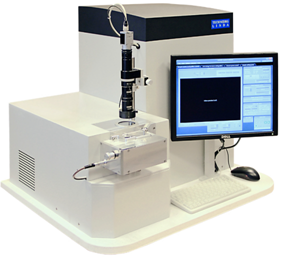

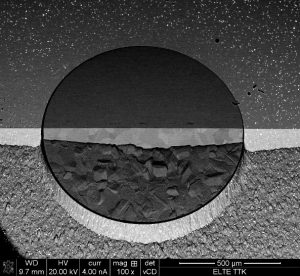

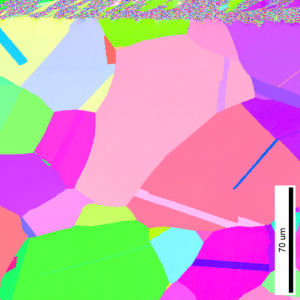

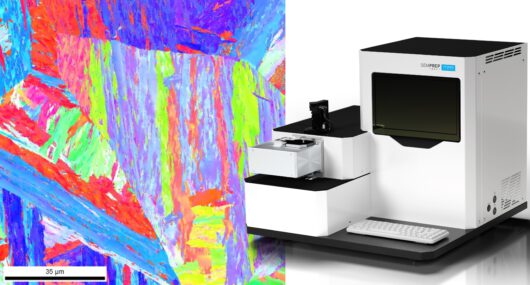

SEMPrep Smart

New generation ion etching system for cross-sectional cuts and damage-free polishing of the sample surface for SEM and EBSD users

- Simple and automated operation

- Largest energy range on the market (<100 eV-16 keV)

- Unique pre-tilted sample holders for angled cuts (30°, 90°)

- +/- 1 µm positioning accuracy for cross-section

- Sample size up to 50mm diameter

- Load lock system for quick sample exchange

- Optional vacuum transfer unit

- Liquid nitrogen or Peltier cooling option

- Oil-free vacuum system

For TEM users:

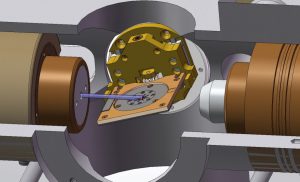

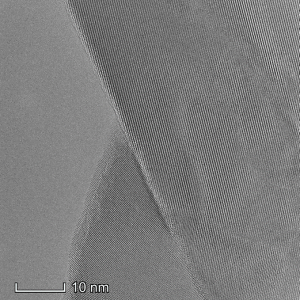

UniMill

Fully automated ion beam thinning system for TEM/XTEM sample preparation

- Easy to use and automated operation

- Widest energy range on the market (100 eV- 16 keV)

- Automatic perforation detector

- Load-lock system for fast sample exchange

- Liquid Nitrogen cooling option

- Online monitoring and support

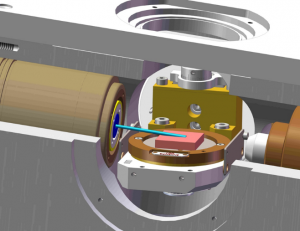

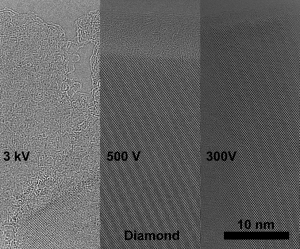

Gentle Mill

Ion beam workstation for final cleaning and end-polishing of highest quality TEM/FIB samples

- Automated operation

- The final step for a perfect result

- vacuum transfer shuttle

- Special adaptor for Hitachi microscopes

- Online monitoring and support

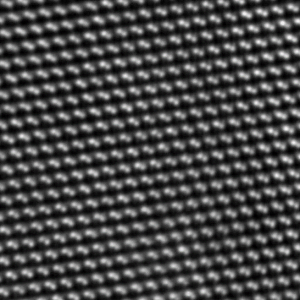

MAG*I*CAL

Traceable transmission electron microscopy calibration sample

TiDisc

Special embedding grid for TEM/XTEM samples